Some laboratory processes are time-consuming and tedious. Automation highly manual processes such as nucleic acid extraction can increase your lab’s throughput and improve the overall consistency of your results. Unfortunately choosing and implementing one of these systems can seem overwhelming. As you begin to evaluate the automation needs of your lab, one of the first decision points is the type of platform you need. Do you need a liquid handler or a magnetic particle mover?

What is a Particle Mover?

As the name implies, magnetic particle movers such as the Maxwell® RSC 48 or KingFisher systems use magnetic probes or tips to move magnetic beads or particles from well to well. These platforms are easy to program and use and often cost less than liquid handling systems. They work well for nucleic acid extraction, protein purification and cell isolation but are not as versatile as a liquid handling system. Depending upon the system you choose, they might require manual reagent dispensing and may or may not have sample tracking capabilities or the ability to be integrated with a liquid handling system.

Using magnetic particle-based methods, however, does not limit you to choosing a particle mover. For example, the Maxwell® HT chemistries are compatible with all major liquid handling platforms.

What is a Liquid Handler?

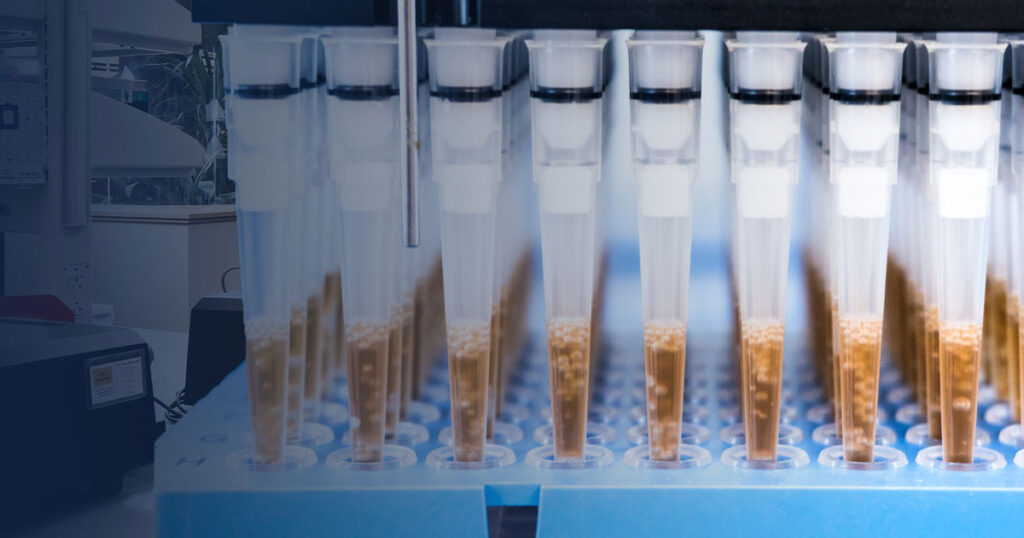

Liquid handlers use robotic arms equipped with motorized pipette tips to dispense liquids into wells or tubes. Highly versatile, these instruments can be programmed to support a wide range of laboratory processes but are more expensive and more challenging to program and use than their particle-moving cousins. Liquid handlers offer great flexibility, with the ability to pipette a wide range of sample types, and often can do so directly from primary collection devices. These instruments can also incorporate sample tracking, ensuring that you know where each sample is at every step of the process.

When evaluating the option of adding a liquid handler, there are several parameters to consider. Perhaps the biggest is what throughput you need, but in tandem with this, you should think about what volume you need the platform to accommodate. For example, 8-channel platforms can typically handle a volume range between 1µl and 5ml; whereas 96-channel platforms can handle volumes up to 1ml. Other, but equally important, parameters to consider include what hardware (e.g., heating and cooling blocks, magnetic stands, barcode readers, etc.) will you need to incorporate, and will you need redundancy to ensure that you don’t lose time if an instrument requires maintenance. Finally, an aspect that is often overlooked in your facility’s capabilities. Can your facility accommodate all the things needed for a liquid handler installation, including access to the desired location, laboratory space and structural support and access to electrical outlets?

Choosing an Automation Platform

Moving from a manual to automated workflow can feel like a monumental undertaking. From defining a platform type to picking the final instrument, there are so many parameters to consider. For help in answering some of these questions, visit the Lab Automation Resource Center. Use this collection of resources to help navigate the complex world of laboratory automation.

Are you interesested in bringing automation to your lab? This video gives you an overview of our upcoming webinar. Register for the lab automation webinar today.